Custom foam packaging significantly enhances the protection of heavy items during transport and storage by providing a precise fit that minimizes movement and shields against impact and compression damage. This packaging is increasingly being made from eco-friendly materials such as cornstarch or soy, or from recycled content, offering a sustainable alternative without compromising on safety. The shift towards sustainable packaging solutions reflects the growing consumer and industry focus on environmental stewardship. These innovative foam options maintain their protective qualities while conserving energy and resources in manufacturing, thus reducing carbon footprints and meeting the demand for sustainable packaging. Companies adopting these practices not only improve their brand image among environmentally conscious consumers but also fulfill their corporate sustainability goals. The advancements in custom foam packaging combine robust safety measures with a commitment to ecological responsibility, setting new industry standards for sustainable practices while ensuring the safe delivery of heavy items. Keywords: Custom foam packaging, Eco-friendly foam packaging, Protective foam packaging.

Exploring the protective potential of custom foam packaging for heavy items, this article delves into the material and design innovations that offer unparalleled safety during transit. We examine how eco-friendly options in foam packaging are not only advantageous over traditional methods but also contribute to sustainability efforts. From a detailed guide on designing protective foam packaging to case studies showcasing its successful implementation, this piece highlights the pivotal role of this material in safeguarding heavy items while promoting environmental consciousness.

- Understanding the Role of Custom Foam Packaging for Heavy Items

- Material Considerations in Eco-Friendly Foam Packaging Solutions

- Designing Protective Foam Packaging: A Comprehensive Guide

- The Advantages of Custom Foam Packaging Over Traditional Methods

- Innovations in Eco-Friendly Foam Materials for Sustainable Packaging

- Case Studies: Successful Implementation of Custom Foam Packaging Strategies

Understanding the Role of Custom Foam Packaging for Heavy Items

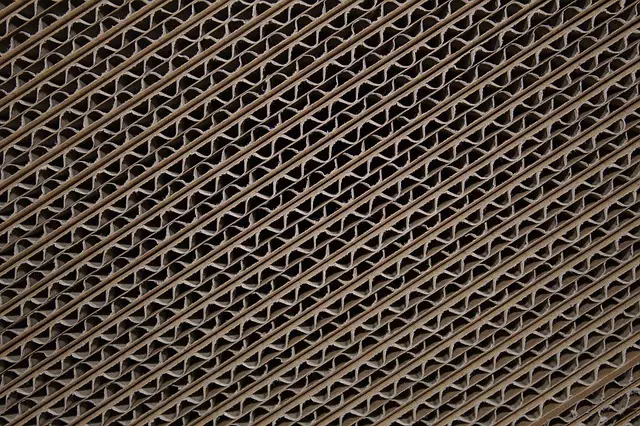

Custom foam packaging plays a pivotal role in safeguarding heavy items during transport and storage, ensuring their integrity remains intact upon arrival. The design and engineering of such packaging are tailored to accommodate the unique dimensions and weight distribution of each item, providing a snug fit that minimizes movement and prevents damage from impacts or compression. This bespoke approach not only enhances protection but also allows for optimal use of materials, which is where eco-friendly foam packaging comes into play. By utilizing sustainable materials and innovative manufacturing processes, these packages reduce environmental impact while maintaining high performance. The eco-friendly aspect addresses the growing concern for sustainability in shipping, making it a responsible choice for businesses looking to minimize their carbon footprint without compromising on the protective capabilities of the foam. This commitment to both functionality and ecological responsibility positions custom foam packaging as a forward-thinking solution in the logistics industry, catering to the needs of heavy item transportation with an eye towards a greener future.

Material Considerations in Eco-Friendly Foam Packaging Solutions

In recent years, the demand for sustainable packaging solutions has surged as both businesses and consumers seek to minimize environmental impact. Custom foam packaging stands at the forefront of this eco-conscious shift, offering protective properties that ensure heavy items remain undamaged during transit. When considering eco-friendly foam packaging options, material selection plays a pivotal role. Traditional petroleum-based foams are being replaced with biodegradable and recyclable alternatives such as cornstarch, soy, or recycled materials. These innovative foams not only provide the same level of protection but also reduce the carbon footprint associated with packaging waste. The transition to eco-friendly foam packaging is a testament to the industry’s commitment to sustainability without compromising on functionality.

Furthermore, the pursuit of sustainable practices extends beyond the choice of raw materials. The manufacturing process of custom foam packaging must also be environmentally sound. This includes energy conservation, reduced emissions, and efficient use of resources throughout production. Additionally, designing packaging that optimizes material usage without compromising on the item’s safety during shipping is crucial. By adopting these practices, companies can offer protective foam packaging solutions that align with both environmental standards and the growing consumer demand for sustainable options. This approach not only aids in preserving natural resources but also positions businesses as responsible entities within the marketplace.

Designing Protective Foam Packaging: A Comprehensive Guide

When it comes to safeguarding heavy items during transportation or storage, custom foam packaging stands out as a highly effective solution. This type of packaging is engineered to fit the unique dimensions and contours of each item, providing a level of protection that off-the-shelf solutions simply cannot match. The design process for custom foam packaging begins with a thorough understanding of the item’s weight, size, and the types of forces it may encounter during handling and transport. This ensures that the foam material is cut, molded, or machined to perfectly cradle the item, minimizing the risk of damage from impacts, pressure, or vibration.

In the realm of sustainability, eco-friendly foam packaging options are gaining momentum as businesses and consumers alike prioritize environmental responsibility without compromising on protection. These green alternatives utilize materials such as recycled content or biodegradable substances that offer comparable protective capabilities to traditional foams. The commitment to eco-friendly practices not only reduces the ecological footprint but also aligns with corporate sustainability goals, making it a wise choice for companies looking to enhance their brand image and appeal to a conscious market. Advanced design software and materials science have paved the way for these environmentally conscious solutions, ensuring that even as the industry moves towards greater sustainability, the integrity and safety of heavy items are not compromised.

The Advantages of Custom Foam Packaging Over Traditional Methods

Custom foam packaging presents a range of advantages over traditional packing methods, particularly for heavy items that require robust protection during transit. Unlike one-size-fits-all solutions, custom foam is tailor-made to fit the precise dimensions and contours of the products it envelopes. This bespoke approach not only reduces material waste but also enhances protective capabilities by providing a snug fit that minimizes shifting and potential damage during handling and transport. The use of eco-friendly foam materials further underscores the environmental responsibility of businesses opting for this packaging method. These sustainable options offer a green alternative to conventional packing materials, contributing to reduced carbon footprints and aligning with increasing consumer demands for sustainable practices without compromising on the protective qualities necessary for heavy items. The result is a packaging solution that is both adaptable and resilient, ensuring the safe delivery of products while demonstrating a commitment to environmental stewardship.

Innovations in Eco-Friendly Foam Materials for Sustainable Packaging

The realm of packaging has seen significant advancements with the advent of eco-friendly foam materials that offer comparable protective capabilities to their traditional counterparts while being more sustainable. Custom foam packaging solutions have evolved to incorporate biodegradable and recyclable components, reducing the environmental footprint of shipping heavy items. These innovative foams are engineered to provide exceptional shock absorption and cushioning, ensuring the safety of products during transit. They are crafted from renewable resources or recycled content, aligning with global sustainability initiatives. The shift towards eco-friendly foam packaging is a testament to the industry’s commitment to protecting both the planet and the goods being transported. Companies across various sectors are adopting these sustainable materials to meet growing consumer demand for responsible packaging options that do not compromise on quality or protection. As a result, the custom foam packaging market is rapidly expanding, offering solutions that are as effective in preserving items as they are in preserving our environment.

Case Studies: Successful Implementation of Custom Foam Packaging Strategies

Across various industries, custom foam packaging has proven to be a game-changer for shipping heavy items safely and efficiently. One notable case study is that of an electronics manufacturer who transitioned to eco-friendly foam packaging solutions. This change not only reduced their carbon footprint but also significantly decreased damage during transit, leading to cost savings and improved customer satisfaction. The custom foam inserts were precision-engineered to fit each product model perfectly, providing superior protection against impacts and vibrations that could otherwise lead to electronic component failure.

Another case study involves a specialized transportation company dealing with the logistics of moving heavy machinery. By adopting a bespoke foam packaging approach, they reported a 25% reduction in shipping-related damages. The custom designs allowed for the secure encasement of sensitive components, which were previously prone to damage during handling and transport. This switch to tailor-made protective foam packaging led to increased reliability, customer trust, and an expansion of their service offerings due to the enhanced reputation for safe delivery of high-value items. Both instances highlight the tangible benefits of custom foam packaging in mitigating risks associated with the transportation of heavy goods, thereby ensuring their integrity from origin to destination.

Custom foam packaging emerges as a versatile and eco-conscious solution for safeguarding heavy items during transit. This article has explored the multifaceted benefits of adopting such packaging, from its protective qualities to its role in sustainable practices. By considering the right materials and innovative designs, businesses can significantly enhance the security of their products while also minimizing their environmental footprint. The case studies presented demonstrate the tangible advantages that companies have experienced by transitioning to eco-friendly foam packaging solutions. In conclusion, this overview underscores the importance of integrating custom foam packaging into logistics and supply chain operations for both practical and ecological reasons. It is a forward-thinking choice that aligns with the growing demand for responsible packaging alternatives.